Beginning in June 2019, doctors in a small city of Wisconsin noticed a sudden rise in lung-related illnesses. Each of the cases was similar, yet they did not follow the same path of other documented lung illnesses, such as pneumonia. This was something new – and they were right.

After 54 deaths and over 2,400 people sent to the hospital, federal authorities and researchers honed in on the culprit – vitamin E acetate.(1) More importantly, it was found that this compound tested positive in illicit THC vape products that were purchased on the street or via online shops.

The vape industry for cannabis and tobacco products came to a screeching halt. What was once a multi-billion dollar sector was now poised for a complete collapse as legislators and lawmakers began pointing fingers as the vape scare raged on.

However, once the CDC pinpointed the cause of the outbreak and concluded that illicit manufacturers were to blame, the vape industry is experiencing a rise to its former heights – and beyond.

However, the latest vape scare came with a price. The industry must collectively change to ensure compliance with state and federal regulators. Aside from the vape product itself, vape hardware must change to keep consumers safe and to keep your business out of the iron-sights of regulators.

If you own a cannabis extraction facility or manage a vape production facility – read along.

Get Your Cartridges Tested

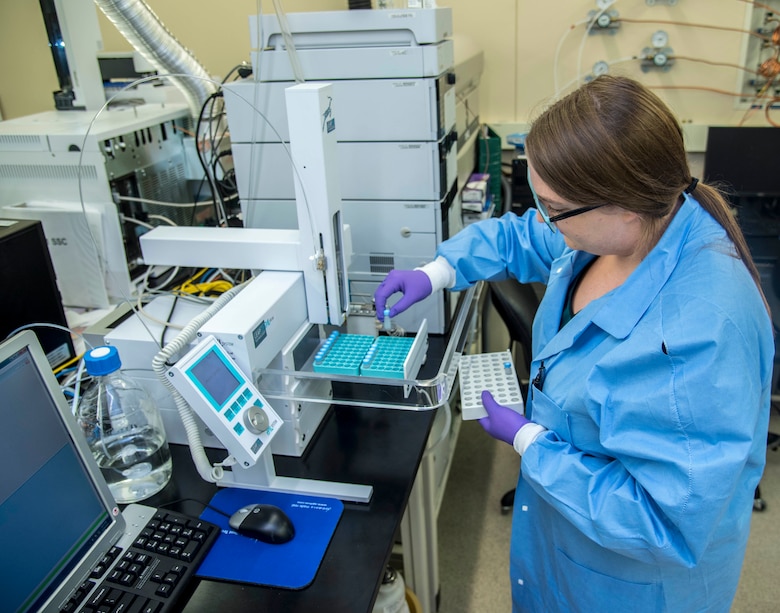

There’s no better time than now to get your cartridges tested to ensure that your vape company remains in compliance with regulations. Unless your business has the capacity to do quality control checks in-house, then you’ll need the help of a third-party to ensure your cartridges are free of contaminants and are faultless.

Not only does it mean a better and safer experience for the end-user, but it also reduces the instance of returns/recalls. By reducing the rate of returns, your business will turn a quicker profit.

The balance of regulation, client satisfaction, and consumer safety is met by having your cartridges tested.

Enhance Quality Control Measures

Quality control is beyond necessary across every manufacturing channel. From the tiniest screw to an intricate piece of hardware – everything must undergo a safety test that meets specific standards.

The standards for the vape industry are continuously changing, however, regulators all agree that they want to ensure that vape manufacturers are producing clean cannabis extracts without additives into cartridges that work.

There have been many instances where vape cartridges break, leak, or overheat prematurely. The time is now to step up your cartridge safety before you’re forced to.

Upgrade Your Vape Cartridge Hardware

The vape scare left many consumers and regulators on the edge of their seats. Although the vast majority of vape products were legitimate and untainted by vitamin E acetate – the damage was done.

Upgrading your vape products with enhanced hardware is an incredible way to recapture the confidence that so many vape companies once enjoyed. As a business owner or manager of a cannabis extraction facility, you want to ensure your product is enjoyed safely and carried by legal marijuana dispensaries.

If consumers are weary of your product because they contain “old” parts, then you may see a drastic drop in sales. Any business-minded individual knows that change is necessary, and we’re currently in a transitional phase.

Switch to Tamper-Proof Mouthpieces

Aside from keeping your clients happy and the end-user absolutely safe – what about from a legal standpoint?

The revelation from the CDC spurred the FDA to come down hard on all vape companies – not just those related to cannabis.

One of the most notable changes from the FDA is that from this point on, all vape companies must comply with preventing access by minors. (2)

If you’re wondering how you can prevent minors from accessing vape cartridges filled with potent THC, it’s through the use of press-fit mouthpieces that are entirely tamper-proof. The overall vape industry is quickly moving away from twist-top mouthpieces and transitioning to the press-fit design because it prevents content exposure.

Once a manufacturer installs the press-fit mouthpiece, the end-user cannot remove it. This is seen as a child-safe and tamper-proof method that complies entirely with the wishes of the FDA.

Furthermore, this method stops end-users from removing the mouthpiece easily to add additional ingredients into the vape product. In other words, the press-fit design is a protective measure for end-users and for your business.

The last thing your cannabis extraction or vape company needs is a sudden report that your product made someone sick – although they added additional “flavorings” to the cannabis extract.

The Success of Your Business Relies on Compliance

Ultimately, the vape scare has changed the cannabis extraction and vape industry forever. Some may argue that it was better before; however, the end result is a focus on consumer safety.

Overall, upgrading your vape hardware should be seen in a positive light because it only adds to your company’s value. Legal cannabis dispensaries were also affected by the vape scare heavily. Therefore, it only makes sense that they will want to only carry safe, reliable, and high-quality vape cartridges that are made from compliant hardware.

With the help of a few uncomplicated hardware upgrades for your cannabis or vape business, you’ll find success quickly by staying ahead of the curve.